Thanks to the close cooperation with the FH Aachen – University of Applied Sciences and especially with the facility of mechanical engineering and mechatronics, as an affiliate institute we are able fall back on the majority of commercially available additive manufacturing processes and machines.

Since 1987 approximately 250 machines for industrial use and tripple the amount of so called “fabbers” also known as Desktop 3D-Printers for personal use for manufacturing physical parts from digital 3D-data have been developed and introduced on the market.

Due to the close relationship in research and development with the FH Aachen we are able to put many of those manufacturing processes for the production of components from polymers and metals to use at the location of Aachen and make them available to our customers.

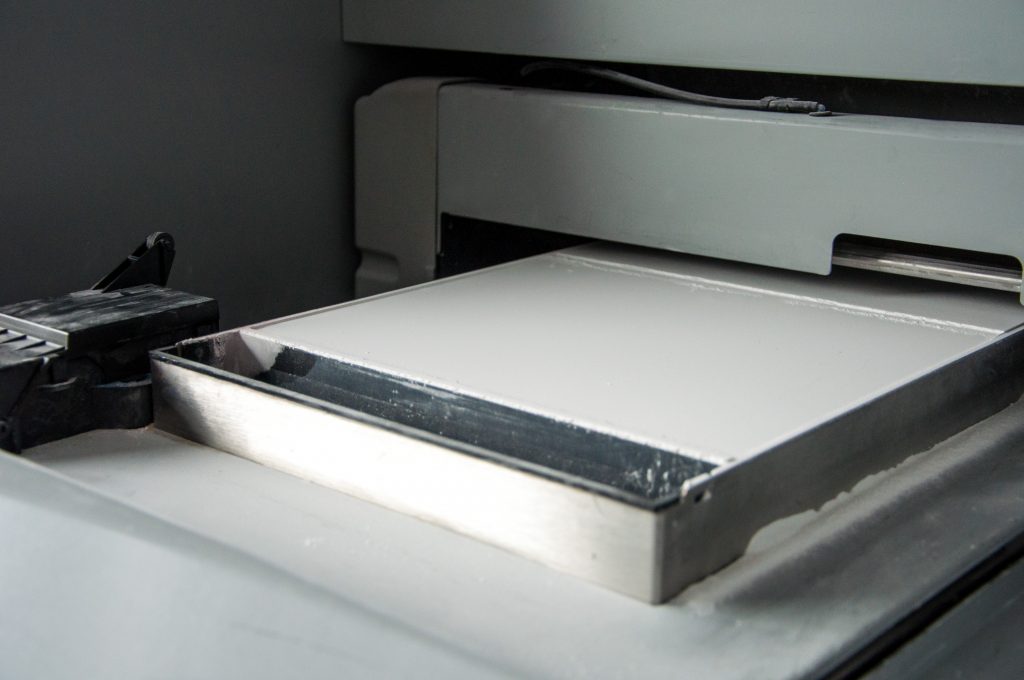

Concept Laser M1cusing

AM Process |

LPBF |

Max. Build Space |

L 245 mm W 245 mm H 250 mm |

Materials |

Metal |

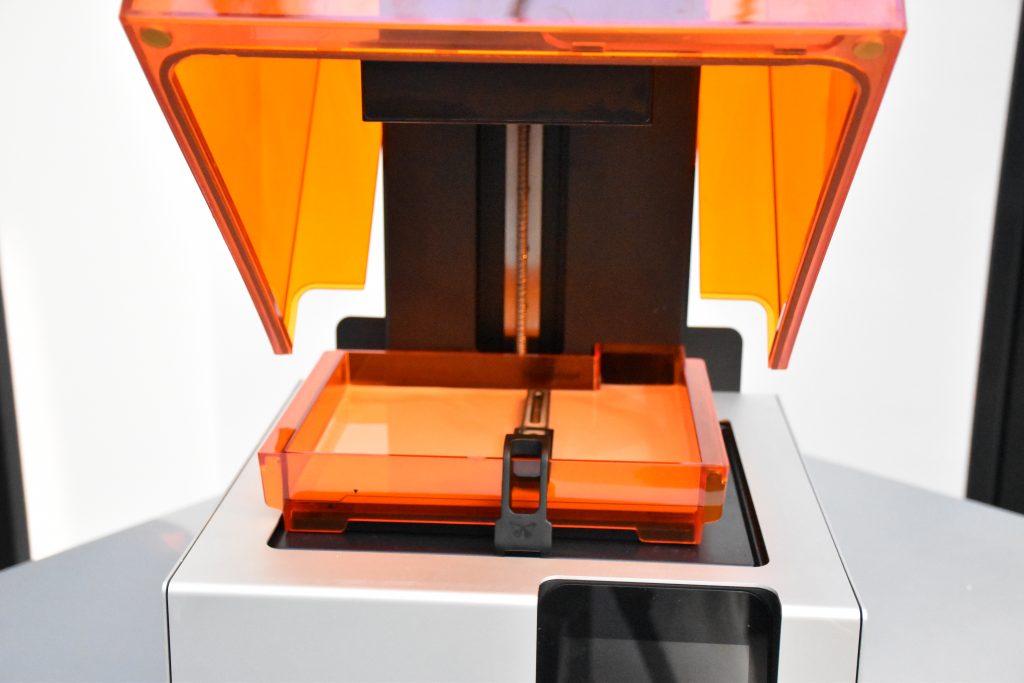

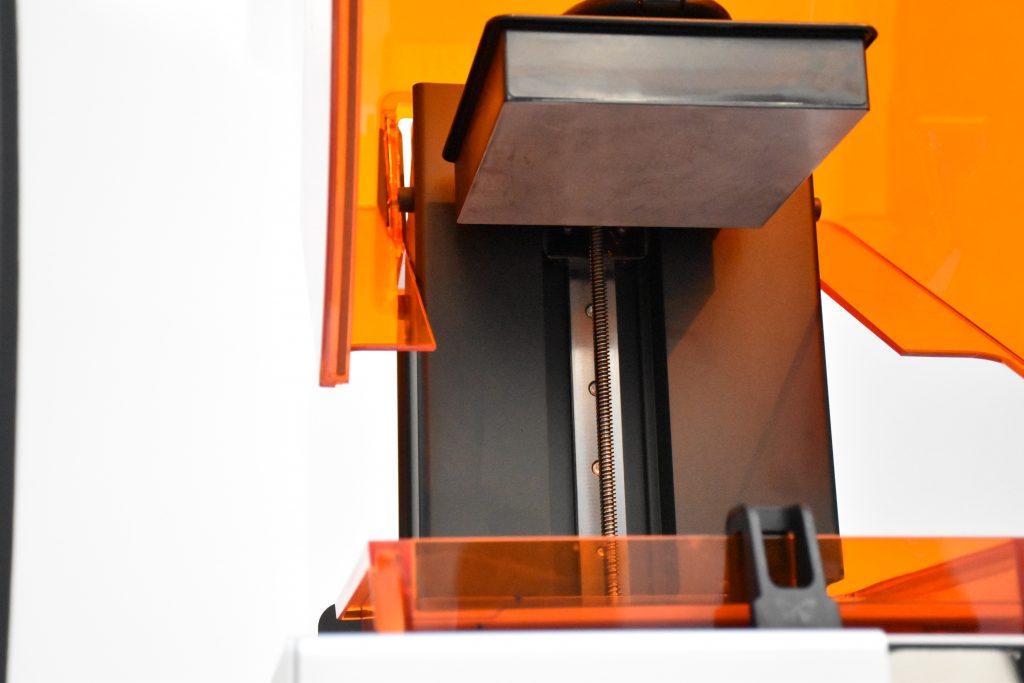

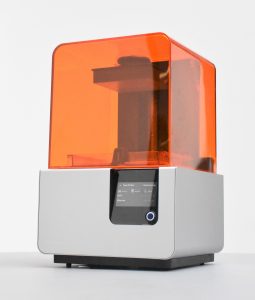

Formlabs Form 2

AM Process |

Stereolithography |

Max. Build Space |

L 145 mm W 145 mm H 175 mm |

Materials |

Photopolymer |

More pictures of the Form 2

Creality CR-10

AM Process |

Extrusion |

Max. Build Space |

L 450 mm W 450 mm H 470 mm |

Materials |

Polymers |

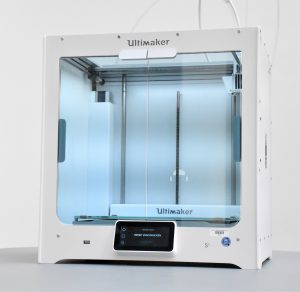

Ultimaker S5

AM Process |

Extrusion |

Max. Build Space |

L 330 mm W 240 mm H 300 mm |

Materials |

Polymers |

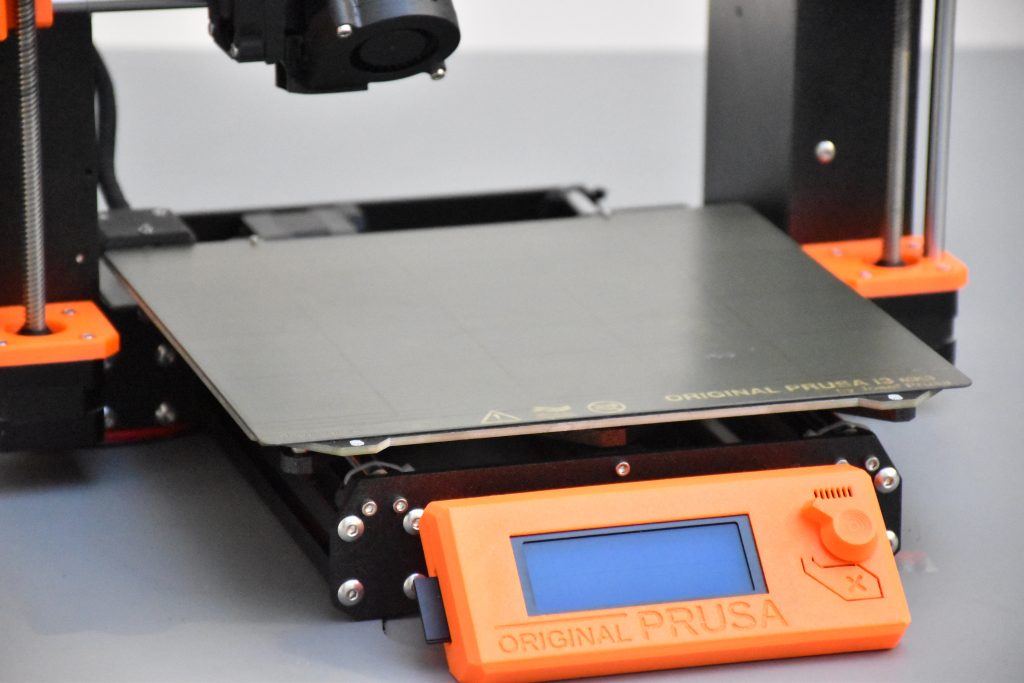

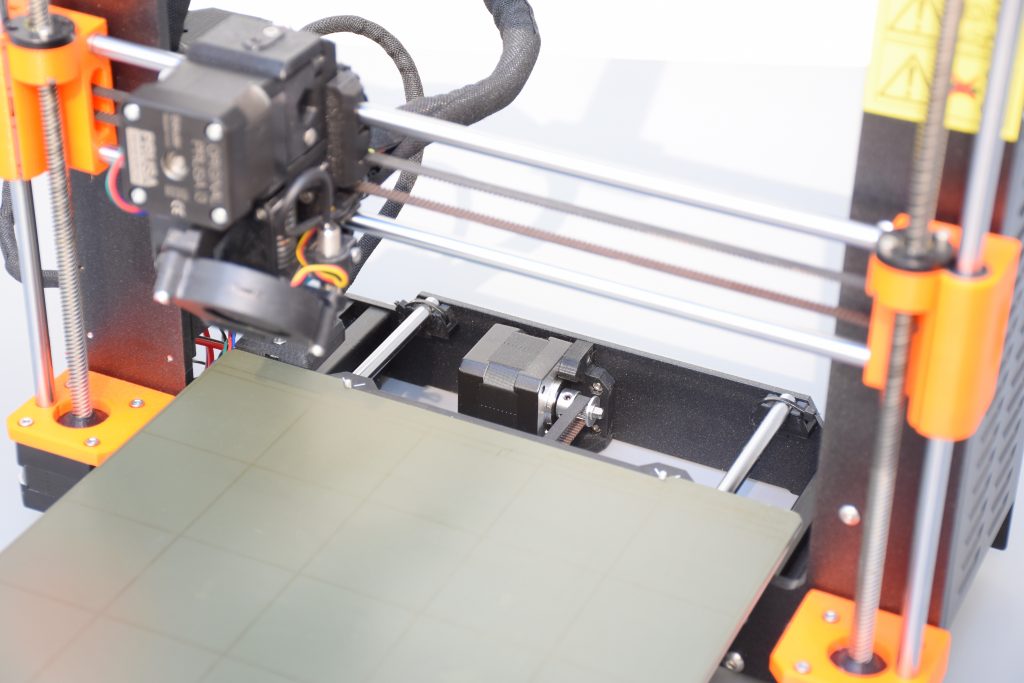

Prusa MK3S

AM Process |

Extrusion |

Max. Build Space |

L 250 mm W 210 mm H 210 mm |

Materials |

Polymers |

More pictures of the MK3S

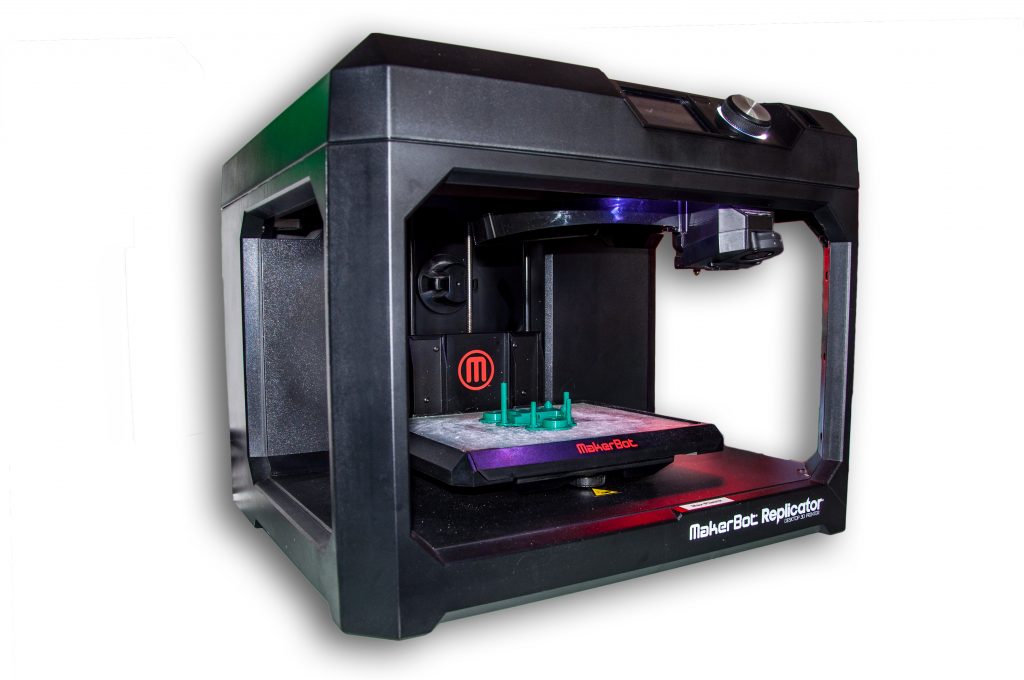

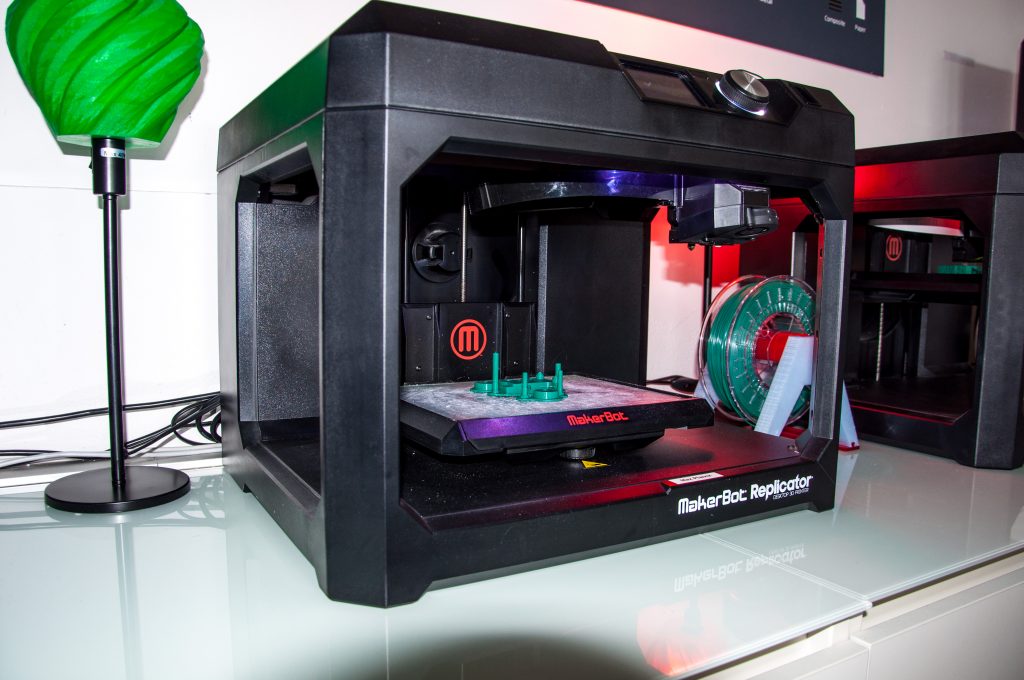

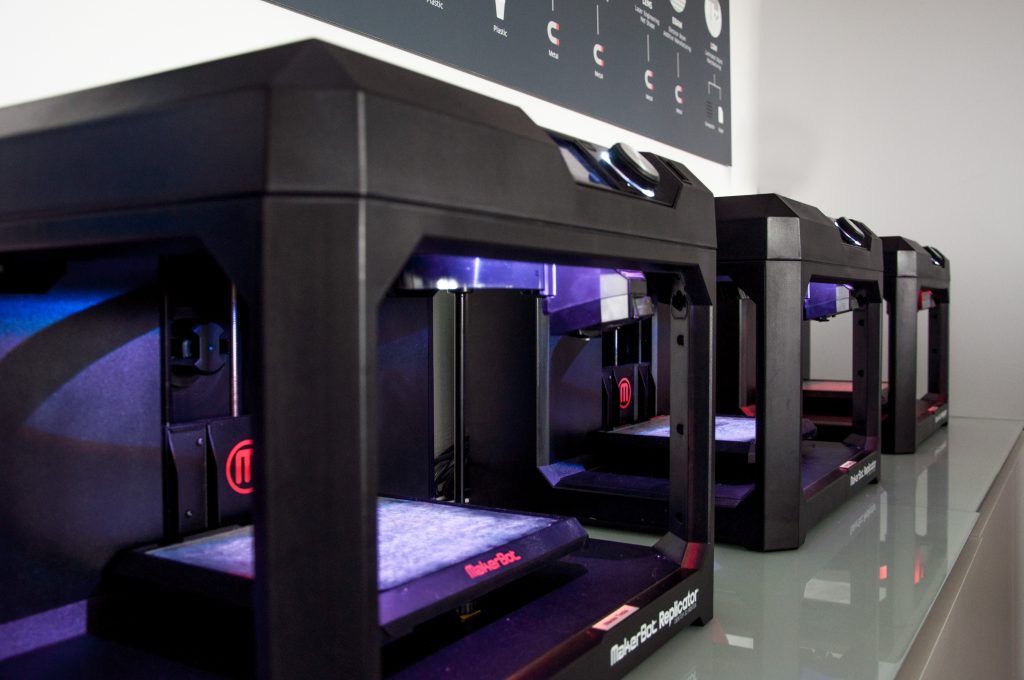

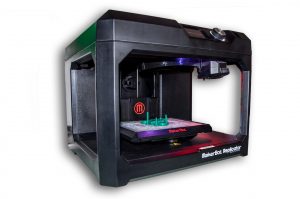

Makerbot Replicator

AM Process |

Extrusion |

Max. Build Space |

L 250 mm W 200 mm H 150 mm |

Materials |

Polymers |

More pictures of the Makerbot

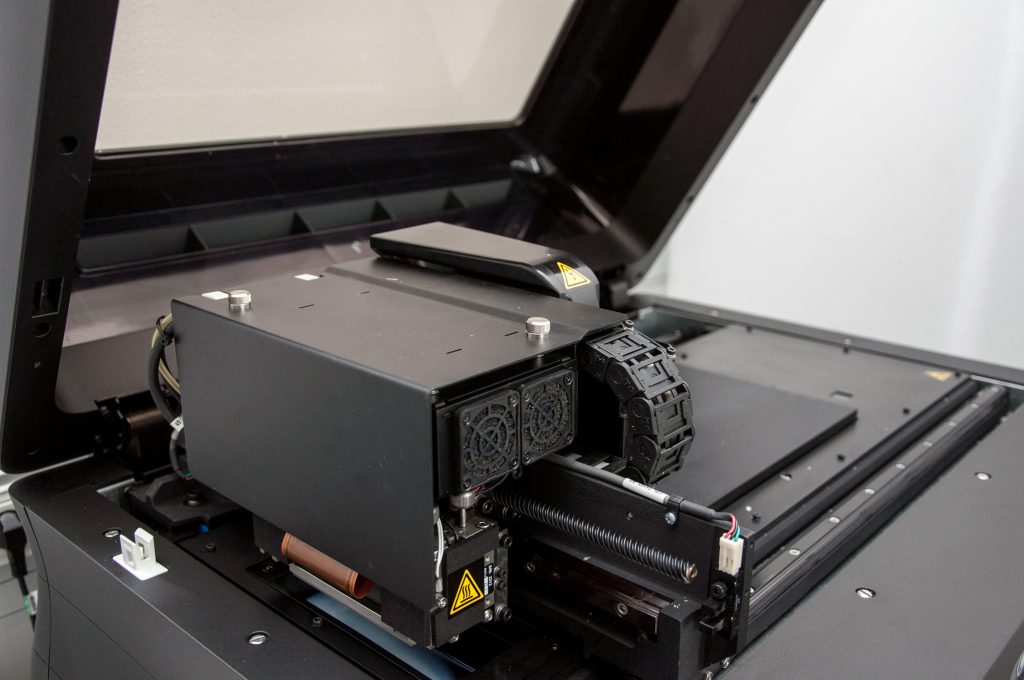

Objet 24

AM Process |

Polymerisation |

Max. Build Space |

L 250 mm W 250 mm H 300 mm |

Materials |

Polymers |

More pictures of the Objet

Z-Corp Zprinter 450

AM Process |

Powder binder |

Max. Build Space |

L 250 mm W 250 mm H 300 mm |

Materials |

Polymers |